Centrifugal Pump Solutions

Maintenance & Service Solutions

Repair

Resimac Protective Coatings

Filters for Vacuum Pumps

Vacuum Instruments

Engineered Systems

Centrifugal Pump Solutions

Maintenance & Service Solutions

Repair

Resimac Protective Coatings

Filters for Vacuum Pumps

Vacuum Instruments

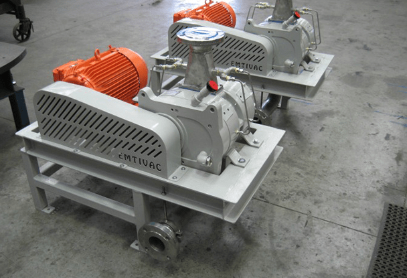

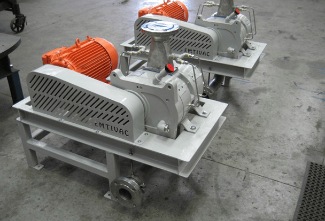

Svc Dry Screw Vacuum Pumps

SVC dry screw vacuum pumps are for chemical and industrial process applications. These are an efficient, cost effective, low maintenance solution for aggressive applications, compliant with restrictive international environmental regulations.Stand-alone performance from 110 to 2,700 m3/hr with levels to 0.05 mbar absolute.

Pompetravaini Liquid Ring Vacuum Pumps

Manufactured in Italy, Pompetravaini is one of the world’s leading manufacturers of single and two stage liquid ring vacuum pumps with suction capacities from 4 to 3,500 m3/hr capacity and levels to 10 mbar absolute. Pompetravaini has the flexibility to manufacture with special materials and seals to suit your unique requirements.

Resimac

Protective Coatings

Emtivac Oilsys Packages

Steam Ejector Technology

FLO-MASTER Pumps Australia

Mobile Suction Systems

Side Channel Blowers

Laboratory Equipment

Instrumentation

Soil Remediation Systems

Resimac Protective Coatings

Emtivac are specialist Pump Repairers to major industry throughout Australia and are proud to be appointed as an approved Renroc Group - Service Partner Applicator.Renroc Group Australia is the sole distribution and technology partner for Resimac Composite Coatings throughout Australia and Papua New Guinea. In collaboration with Emtivac Australia, Renroc Group Australia can supply full Scopes of Work and all specification services when any coating work is to be performed. Emtivac performs the surface preparation and quality application of specialised Resimac Composite Coatings to all styles of equipment and specialises in the supply and refurbishment of Vacuum Pumps throughout Australia.

Emtivac N2Be Liquid Ring Vacuum Pumps

The Emtivac N2BE range of large capacity vacuum pumps is manufactured to our exacting standards to meet the requirements of the toughest applications in the mining, paper, sugar and power industries.

- Suction capacity from 1,800 to 70,000 m3/hr

- High efficiency variable discharge port

- Up to33 mbar Abs

- Available in cast iron, 304, 316 or Duplex SS

Multistage Systems

Some applications require large suction capacities at high pressure. Often in this case, a multistage vacuum pump system is required. Emtivac designs and manufactures hybrid systems using steam ejectors or roots type mechanical boosters in series with a suitable backing vacuum pump, liquid ring or rotary vane, in order to reach the higher levels. Almost any combination of suction capacity and inlet pressure can be achieved with these arrangements.

Liquid Ring Compressors

The liquid ring compressor is the ideal machine for compressing wet, corrosive and flammable gases. Emtivac manufactures complete packages with capacities from 4 – 70,000 m3/hr. Flare gas recovery packages to API 681 standards complete with all electrical controls and instrumentation designed and manufactured by Emtivac. A wide range of materials and mechanical seal options are available.

Pompetravaini-Nsb Api Sb Liquid Ring Compressor For Gas Processing

The liquid ring compressor is the ideal machine for compressing wet, corrosive and flammable gases. Emtivac manufactures complete packages with capacities from 4 – 70,000 m3/hr. Flare gas recovery packages to API 681 standards complete with all electrical controls and instrumentation designed and manufactured by Emtivac. A wide range of materials and mechanical seal options are available.

Rotary Vane And Claw Vacuum Pumps

- Rotary vane vacuum pumps – Oil lubricated with suction capacities from 3 to 1,600 m3/hr and up to 0.5 mbar Abs

- Claw type vacuum pumps – Dry running, low maintenance design, suction capacity from 100 to 600 m3/hr

- Rotary vane vacuum pumps – Carbon vane with suction capacity from 3 to 500 m3/hr and up to 100 mbar Abs

Baratti Blowers

We supply Baratti blowers with patented high efficiency ‘gamma twin lobe system’ technology. They feature:

- Power consumption reduction by 10 to 20 per cent

- Reduced discharge pulsation by 85 per cent

- Lower noise level than raditional blowers

- Lower temperature rise than traditional blowers

- Pressures up to 130kPa (with reinforced cooling version)

- Vacuum down to -70kPa

- Up to 6,000m3/h individual capacity

- Gas tight versions for hazardous applications

- Constant efficiency and operating temperature from 20 – 100 per cent speed range

- Power consumption reduction by 10 to 20 per cent

- Reduced discharge pulsation by 85 per cent

- Lower noise level than raditional blowers

- Lower temperature rise than traditional blowers

- Pressures up to 130kPa (with reinforced cooling version)

- Vacuum down to -70kPa

- Up to 6,000m3/h individual capacity

- Gas tight versions for hazardous applications

- Constant efficiency and operating temperature from 20 – 100 per cent speed range